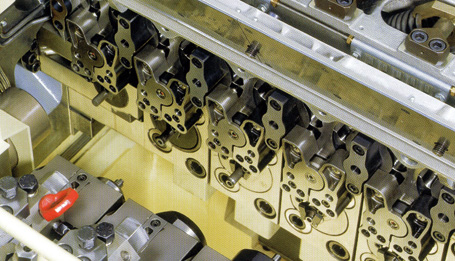

Cold forming

The process of cold forming occurs through the use of a number of presses in a progressive manner. Based upon the product to be manufactured 4, 5 or even 6 dies are utilized.

The speed of production is much greater than that of the production through turning. We produce, for example, 150 bolts a minute. Conventional turning allows instead to produce only two or three pieces a minute.

Another advantage of cold forming consists of less wasted production materials.

It’s possible to obtain the same tolerances but with an important reduction in terms of costs in relation to conventional turning.

In addition, we seek to use cold forming technology also for more complex products substituting more and more conventional turning also in their production.

|